How is it Done?:

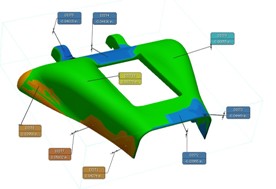

Your part is scanned to produce point cloud data. That data is converted to a clean mesh file that is then placed on top of the original CAD data. Rapidform XOV performs a best fit function by determining the most logical way to line up the data. This function is performed 20 times to ensure that the data is lined up perfectly. Now the scan data can be compared to the original CAD data to determine the differences. Color deviation maps will show where the part surface is above or below the design surface. Many other dimensional operations can be performed.

What do you get?:

Absolute Geometries will supply various inspection reports and files

to help you analyze your product:

- Interactive 3D models

- Color 3D surface deviation maps

- 2D boundary and section deviation maps

- GD&T reports from your supplied drawing