Lawn and Garden Equipment: Chassis Assembly

A lawn and garden equipment manufacturer needed to check the location of a bearing housing that was inserted into a complex plastic assembly.

3D scanning was used to perform this task easily, and some additional problem areas were discovered.

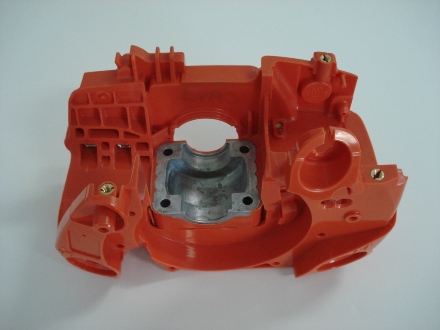

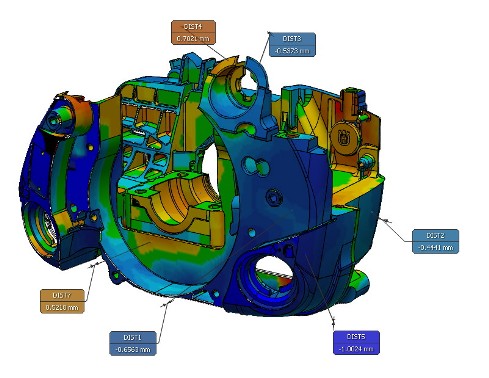

Complex Plastic Chassis assembly.

Complex Plastic Chassis assembly.

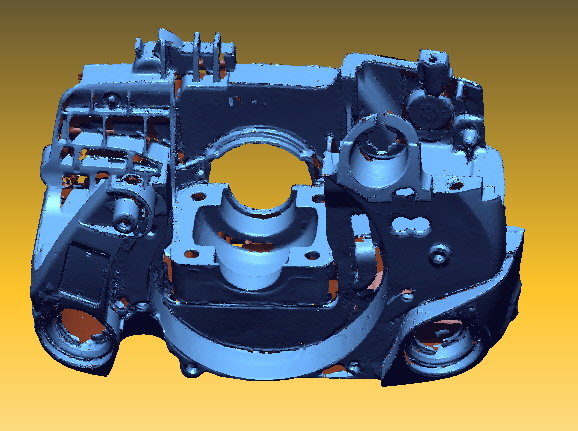

The plastic assembly was scanned to create a 3D mesh file that could be overlaid on the CAD file. Features were analyzed to determine the best fit for aligning the scan to the CAD data.

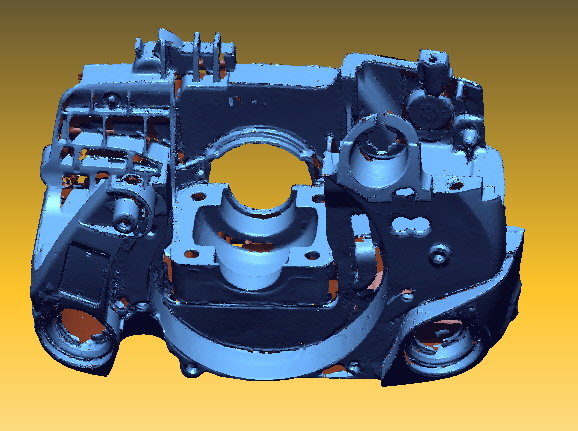

Raw Mesh File

Raw Mesh File

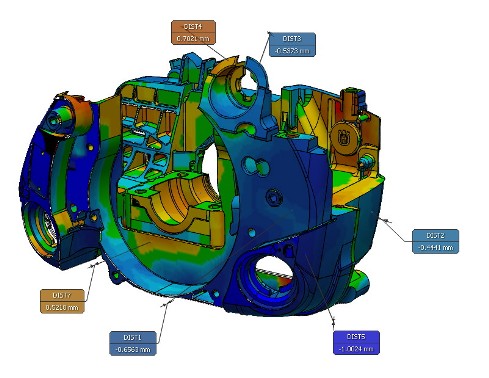

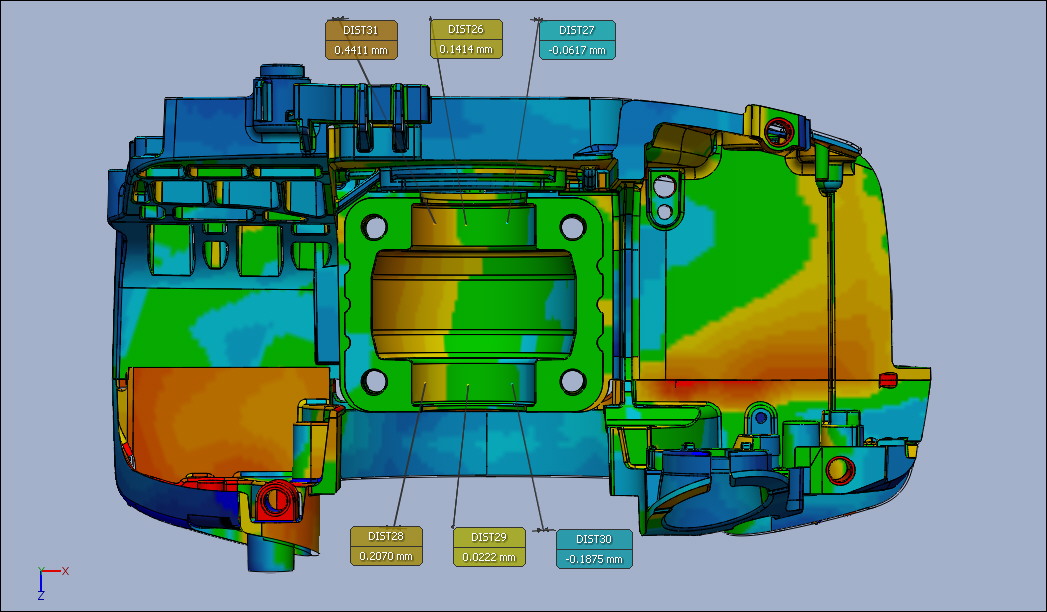

3D Color Deviation Model with Reference Dimensions on Bearing Surface

3D Color Deviation Model with Reference Dimensions on Bearing Surface

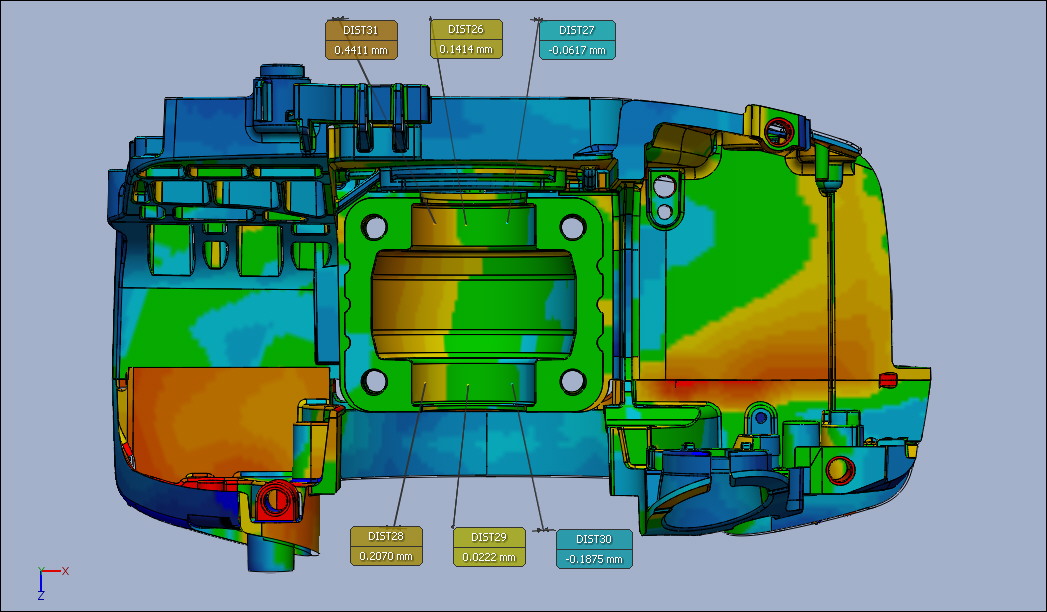

The color deviation map shows where and how much the scan data does not match the design data. Dimensions can be taken at any location. This enabled the exact location of the bearing surface as it relates to the entire assembly to be measured.

Additional issues discovered included a warped feature and excess shrink.

Raw Mesh File

Raw Mesh File 3D Color Deviation Model with Reference Dimensions on Bearing Surface

3D Color Deviation Model with Reference Dimensions on Bearing Surface